Inland Diving Services

Water Tank-Tower Inspection Services: Municipal or Industrial

Since 1995, U.S. Underwater has provided economical and safe diving inspection services to municipalities, water districts, military installations, and industrial facilities, including potable and process water tank inspections, maintenance, and repairs.

In-Service Diver Tank Inspection Services

Draining tanks to inspect or clean them wastes a significant amount of water, thereby costing the community it serves valuable time and money. We offer clients a time-saving and cost-effective alternative for inspecting potable water tanks.

When working in potable water, our professional ADCI-certified divers utilize equipment that meets or exceeds all OSHA and AWWA standards. Inspection equipment includes a chemical resistant dry suit and diving helmet, surface-supplied air, and an audio and video link that allows for two-way voice communication with the diver. All divers and equipment are disinfected to AWWA standards with a chlorine solution before entering potable water.

Our trained inspectors perform both interior and exterior inspections to assure that the tank’s physical integrity, water quality, and security are in compliance with AWWA. All inspections include a professional report containing the following:

- Written report with photos

- Narrated internal video

- Water access hatch, vent and internal/external ladder conditions

- Reporting of sediment/debris levels

- Corrosion estimates (as needed)

- Recommendations for repairs needed per AWWA/OSHA standards

In-Service Sediment Removal

Sediment builds up in almost all water storage tanks. Removing a tank from service can be expensive and time-consuming. Most systems cannot afford to have a storage tank offline. Our sediment cleaning system employs a submersible pump to vacuum sediment out of the tank while it remains in-service.

Leak Detection/Epoxy Leak Repairs for Water Towers and Tanks

U.S. Underwater can perform water tower leak detection services and repair minor leaks while your potable water tank remains in-service. We use a solventless, 100% solids, corrosion resistant epoxy coating that can be applied to dry or wet surfaces. Our epoxy coating has the following attributes:

- Quick setting

- Hardens in water

- Corrosion resistant

- Meets requirements of NSF standards

- USDA compliant, AWWA approved product

- Works best on steel and galvanized steel

Hurricane Storm Response and Recovery

During the past two decades, U.S. Underwater has been involved in numerous projects to assist clients (both inland and offshore) responding to the impact of hurricanes and tropical storms.

Being based in the Dallas-Fort Worth Metroplex allows our dive teams to coordinate and deploy resources anywhere in the gulf coast area.

We are committed to helping government entities and commercial businesses get their assets back into operation efficiently and safely.

Examples of some of the services we can provide:

On Shore / Inland

- Underwater inspections:

- Dams and levees

- Intake structures

- Docks, harbors and marinas

- Seawall inspections

- Outfalls

- Bridges

- Pipelines

- Dredging, flood debris and sediment removal

- Intake structures

- Retention ponds

- Bayous

- Pipeline scouring and cover surveys

- Pipeline exposure remediation

- Equipment salvage and recovery operations

- Pressure washing and chlorination of potable water storage facilities

- Haz-Mat divers for wastewater facilities

Near Shore / Offshore

- Underwater inspection and damage assessment:

- Rig/Mobile Offshore Drilling Units

- Vessel hull inspections

- Platforms (Level II, III, IV)

- Pipelines

- Scouring surveys and scouring mitigation

- Pipeline stabilization

- Pipeline exposure remediation

- Pipeline scouring and cover surveys

- Boat salvage operations

- Site surveys, site clearance, and debris removal

Underwater Salvage Services

U.S. Underwater has the capability to perform a variety of underwater salvage and recovery projects. Aside from typical boat salvage projects, our divers have located and retrieved sunken equipment, submerged vehicles, and floating intake structures. Over the past two decades, USU has recovered a variety of objects from ponds, lakes, rivers, harbors, lagoons, ship channels, and reservoirs.

Underwater salvage and recovery operations present a multitude of obstacles, including challenges stemming from limited visibility to unknown environmental elements. Each project requires a meticulous rigging and lifting plan to ensure the safety of the dive crew as well as the best possible outcome for the recovery of the submerged object or structure.

A few past project highlights:

- Underwater Habitat Restoration - USU was contracted to perform underwater salvage of the long-abandoned, 'Mermaid Show', as part of a large-scale project to restore the Aquarena Springs theme park to its natural habitat. Divers rigged and removed more than 1 million pounds of concrete embedded in the bottom of the San Marcos River utilizing the second largest crane in the United States. The concrete remains were delivered in 76 truckloads over a two-week period.

River Salvage of Construction Equipment

- Construction Equipment River Salvage – A construction company performing work in the Waco, Texas area had an aerial lift that was staged on a barge in the Brazos River. During construction, the lift fell from the barge into the river bringing the project to a halt. A plan was formulated, and the diver inspected, secured, and removed all tools and components to ensure no objects were dropped during the lift. The dive team carefully rigged the lift and it was extracted with a large crane which set it back on its original equipment barge.

- Lake Salvage of a Barge Structure – USU was contacted by a water district in West Texas to salvage a floating intake structure that sank to the bottom of a lake due to damage by high winds. Utilizing underwater cutting and lift bags, divers floated the barge to the surface in cut sections and secured rigging for the client to bring the structure to safe harbor.

- Underwater Search and Recovery – After a motorist had been missing for several weeks, local authorities suspected the vehicle and the motorist had veered off a road into a nearby lake. USU was contacted to search for the vehicle and retrieve any findings. Divers were able to locate the body in the vehicle, securing rigging so that all contents could be recovered.

If you are looking for one of the top underwater salvage companies for a marine salvage project or have any asset that has been submerged, please contact U.S. Underwater for a professional assessment.

ROV Inspection Services

U.S. Underwater is pleased to offer a budget friendly alternative to the certified diver inspection. Our in-service remotely-operated vehicle (ROV) inspection will provide a general inspection of the water storage facility while also satisfying state and industry regulation requirements. During ROV inspections, no personnel enter the tank, so lockout/tag out procedures and confined space entry permits are not required. The ROV is sprayed with an AWWA-required 200ppm chlorine solution before entering potable water tanks.

The ROV inspection comes complete with a brief video from the live inspection feed along with a written report including photos. ROV inspections meet AWWA tank inspection standards and provide valuable information regarding the general condition of your facility.

A list of recommendations will be provided to ensure your facilities are compliant with state and industry standards.

Benefits of the ROV inspection services include:

- Cost effective for limited budgets

- Provides overall condition assessment of the facility

- Excellent for general inspections

- No downtime

- Limited liability

- No water loss

NFPA 25 Fire Suppression Tank Services

U.S. Underwater has extensive experience with National Fire Protection Association (NFPA) 25 fire suppression tank services and is an associate member of the organization. NFPA code 25 is the baseline for inspection, testing, and maintenance of water-based fire protection tanks and systems. Compliance is imperative to maintain system integrity and ensure fast, effective response in a fire emergency.

These inspections are performed utilizing ADCI-certified commercial divers and industrial equipment while the tanks remain in-service.

Upon completion of each project, we provide a full written report along with a narrated video and a list of recommended repairs based on NFPA standards.

Our NFPA 25 tank service includes the following:

- Internal inspection of all tank components

- External inspection of all tank components

- Ultrasonic thickness testing

- Dry film thickness testing

- Paint adhesion testing

- Sediment removal (as needed)

- Leak detection and repair (as needed)

- Custom fabrication (as needed)

- Underwater welding (as needed)

Intake and Sluice Gate Services

U.S. Underwater has extensive knowledge and experience performing inspection, repair, and maintenance of intake and sluice gate structures for municipalities, river authorities, power plants, and industrial facilities.

We work with each client to provide the safest, most efficient, and cost-effective solutions available. When needed, a thorough site evaluation is performed, and a detailed project plan is provided prior to mobilizing to the project site. Potential hazards are identified in advance, which allows our team of divers to arrive with the proper equipment to perform the project in a safe manner.

Upon completion of each project, we provide the client with a written report, narrated video, and a list of recommended repairs based on state or other applicable standards.

Our specialized service includes the following:

- Intake, outfall, and traveling water screen inspection, cleaning, and repair

- Jetting sediment from inside intake and outfall lines

- Intake screen fabrication and installation

- Gate valve repairs

- Sluice gate inspection, repair, and installation

- Diver-operated dredging of material from in front of intake structures

- Intake bay and pump house inspection, sediment or debris removal

- Zebra mussel removal

- Non-destructive testing (NDT)

- Buoy installation

- EPA316B inspection and upgrades

- Stem shaft repair

Zebra Mussel Removal

The zebra mussel is a filter-feeder (similar to clams and oysters) and lives in freshwater lakes and river systems. Since its introduction into the Great Lakes around 1988, the species has spread throughout North America in canals and rivers, as well as inland lakes. According to Texas Parks & Wildlife, 27 Texas lakes can be classified as fully infested with zebra mussels.

The zebra mussel’s ability to reproduce makes eradication difficult, and the potential damage becomes more costly to owners of freshwater structures.

Industrial and municipal water users experience problems with zebra mussel infestations on external structures such as intakes, as well as internal piping. Zebra mussels can attach to intake screens, trash racks, valves, gates, and pumps. They can also accumulate in canals and balancing reservoirs that can serve as breeding grounds for further infestations.

Power plants are at risk for zebra mussel attachment in the penstocks, turbines, and cooling water system when they do not operate continuously. They can attach to virtually any structure, thus inhibiting water flow. Zebra mussel control and removal is key in preventing unscheduled shutdowns.

U.S Underwater has experience inspecting for and removing zebra mussels by mechanical and hydraulic means.

SEE RELATED EXPERIENCE

HAZMAT Diving

U.S. Underwater provides HAZMAT diving as part of its line of services. Utilizing highly specialized equipment and safety procedures, divers can assist clients with projects related to the following:

- Inspection, maintenance, and repairs (IRM) in wastewater and sewage treatment plant diving

- Pipe penetration services

- Nuclear power plant diving services (radiation dives)

- Chemical plant diving services

- Sludge removal services

We also offer 24-hour emergency service and customized cool suits based on client needs.

For more than 25 years, U.S. Underwater has been supplying clients with safe, sanitary, and economical HAZMAT diving solutions.

SEE RELATED EXPERIENCE

Underwater Welding

U.S. Underwater offers underwater welding services to both inland and offshore clients. We can provide our clients with the formal written welding procedures to the appropriate AWS Standard for topside and underwater welding. The AWS D3.6 Specification is the most widely-used underwater welding specification and considers variables particular to wet welding.

We have experience performing underwater welding repairs in many industrial applications, including:

- Cathodic protection systems

- In-service water tank repairs

- Sluice gate repairs

- Bulkhead repairs

- Hull repair

Underwater Construction Services

U.S. Underwater has the experience and resources to manage turnkey construction and maintenance projects, both large and small. We have been supporting general contractors, engineering firms, municipalities, power plants, and industrial plants with marine construction services for over two decades.

U.S. Underwater works with each client to provide the safest, most efficient, and cost-effective solutions available. When needed, a thorough site evaluation is performed, and a detailed project plan is provided prior to mobilizing to the project site. Potential hazards are identified in advance which allows our team of divers to arrive with the proper equipment to perform the project in a safe manner.

The following is a list of our inland marine construction services:

- Underwater concrete placement, sawing, and repair

- Certified topside and underwater welding

- Trash rack installation and repair

- Outfalls, intakes, and discharge structures

- Port, harbor, and marina support

- Sluice gate installation and repair

- Internal pipe inspection and repair (pipe penetration)

- Pier, piling, and bulkhead repair

- Cofferdam installation

- Dredging and debris removal

- Cooling tower and spray pond cleaning and maintenance

- EPA316B upgrades

- Gate and valve installation and repair

- Epoxy injection/repairs

- Stop log installation/removal

- Sills, seals, guides, shafts, and linkage installation and repair

- Non-destructive testing (NDT)

- Underwater burning/cutting/welding

- Cathodic protection system installation

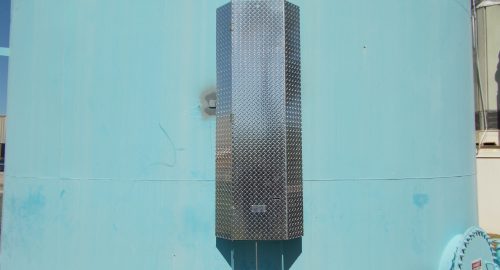

Custom Fabrication

U.S. Underwater maintains a full service, in-house fabrication shop to meet the needs of our clients. With approximately 2,500 sq. ft. of dedicated shop space and an array of welding and fabrication equipment, we can handle jobs both large and small.

Below is a sample of our products:

- Custom vents for water storage facilities

- Intruder protection doors

- Water access hatches

- Ladders and fall protection systems

- Cofferdams/bulkheads

- Catwalks and railings

- Trash racks and bar screens

- Products for water storage tanks are our specialty -

Quality and Durability

We place the same emphasis on quality in our fabrication shop as we do in our diving operations.

The benefits of using our products include:

- High-quality steel, stainless steel and aluminum materials

- Corrosion and chemical resistant parts

- Powder coating instead of painting (powder coat is more durable and scratch resistant)

- One year warranty on products fabricated and installed by a U.S. Underwater fabrication team